The journey of textile fibers: plant fibers

The journey of textile fibers : plant fibers

Organic cotton, linen or hemp, we all know at least one of the fibers or materials used to make our favorite garment, you know, the one we put on every occasion, come rain or shine (although it's a T-shirt...), which does not move despite the weight of the years and which sits proudly in your dressing room!

Unfortunately, we often know very little about the production methods, their intrinsic qualities and their own specificities or the impact of these textile materials. At Maison Izard, we believe that the textile industry has an educational role to play in promoting responsible consumption. And this reasoned consumption cannot pass without the understanding of each resource used and the issues related to each of them.

For this, we invite you to go on a trip and discover a tour of textile fibers, through 3 articles, each linked to a type of fiber or material (vegetable, animal, recycled and new materials). Because of their impact, their implication in the development of fast-fashion, we will voluntarily approach synthetic fibers very little, fibers requiring to be reduced. Indeed, these fibers of chemical origin, although being very useful for their ability not to crease, not to shrink or to be easy to maintain, have greatly contributed to placing the textile industry as one of the industries most polluting in the world. Unfortunately and pragmatically, it is still very complicated to be able to do without these chemical materials in the textile sector. Among the textile fibers (vegetable, natural, recycled and chemical therefore), these chemical materials, widely used in the manufacture of technical clothing for example, represent 68% of the total of the textile fibers used (compared to 24% for cotton, 8% for other plant materials, 6.4% for cellulosic artificial fibres, animal fibers for 1.5% and less than 1% for recycled materials).

Let's start by defining textile fibres. Since Man has always needed to cover himself, especially during the cold season, textile fibers represent the raw materials from which clothes are made, and which therefore meet this natural need.

For this first stage of our tour, we will focus on vegetable textile fibers through cotton, organic cotton, linen, hemp, jute, ramie and artificial chemical fibers.

Cotton: the plant fiber per excellence

Let's start with the most famous and most used textile plant fiber: cotton.

Used for millennia, this vegetable textile fiber was for many centuries the fiber most used in the textile industry. Driven by its practicality, versatility, durability, softness and breathability, cotton saw its use soar until the early 2000s, when synthetic materials arrived on the market and gradually led a significant drop in its use. Today, cotton is mainly produced in 4 countries: China, the United States, India and Brazil. Despite a significant drop in its production volume, the United States remains the main cotton exporter with 37.8% of world cotton exports. On the other hand, European cotton production is in the minority with only 2% of the world production volume, and is largely intended for export. Of excellent quality, it is mainly grown in Greece and Spain and stands out for the length of its fibers and its resistance. In France, there is, for the moment, only one cotton crop, mainly because of our climate which is not necessarily adapted to its development. Indeed, cotton requires a soil temperature above 15°C , an air temperature between 21 and 37°C and no showers during the period of maturation (in summer) and harvest (between September and october). As a result, it is complicated to envisage the development of its culture on a large scale, on the territory.

Now let's look at the different types of cotton fabric. As cotton is a fiber that is particularly easy to work with, there are more than fifteen different cotton fabrics, including:

- The inevitable denim : it is surely the fabric that we all know because it is the fabric of jeans! Tight knit fabric with a colored warp and an ecru weft, it is thick, strong and durable, and is often mixed with softer materials to gain elasticity.

- Cotton twill : thick and resistant, cotton twill is widely used for jackets, work pants or coats. The lining of ourUbac and Avalanche wool coats are also in cotton twill for more comfort and durability.

- Brushed cotton : soft, warm and breathable, brushed cotton is a fabric recognizable to the touch. With a fluffy appearance, it is ideal for winter shirts.

- The timeless corduroy : fabric with emblematic horizontal streaks, it is one of the essential winter fabrics thanks to its warmth, its solidity and its very textured appearance. It is particularly used for making shirts and pants.

- Cotton jersey : ideal for making t-shirts, cotton jersey is a comfortable, soft and easy-care knitted fabric. It is also from this material that ourorganic cotton T-shirts are made!

- Cotton poplin : often used in the manufacture of shirts for its slightly satin appearance and its ability to resist friction, this fine fabric, very pleasant to wear and breathable, is obtained thanks to a very tight weave giving the fabric its characteristic appearance.

- Cotton gabardine : strong, tightly woven fabric that resists creasing well, it is a resistant and easy-care fabric, ideal for making coats.

However, the environmental and social impact of cotton growing is far from trivial. Firstly, cotton being a hydrophilic plant, its cultivation requires a very large quantity of water. For example, the production of one kilo of cotton requires the use of 10,000 liters of water , which represents 2700 liters of water to make a single T-shirt! To this problem of using a limited resource is added that which the largest producing countries (China, United States, India and Pakistan) have experienced in recent years, major droughts and water shortages, a phenomenon which will unfortunately increase in the years to come. Second blocking point, the use of fertilizers, pesticides and insecticides. Cotton is the most pesticide-intensive crop in the world and uses 4% of the world's nitrogen and phosphorus fertilizers . These chemicals lead to a degradation of the quality of soil and water, have a negative impact on biodiversity, and on the health of farmers.

Added to these two elements is the ethics of production. Indeed, although cotton production provides employment for more than 250 million people (nearly 7% of the active population in developing countries), its cultivation is also subject to important economic and social issues. Inhuman working conditions, low selling prices that do not allow for fair remuneration, slavery or child labor , the reality behind cotton growing is often grim.

However, everything is not so dark and does not mean that cotton should be banned from your dressing room. Indeed, there is a more ethical, ecological and responsible cotton: organic cotton.

Cotton or organic cotton, what are the differences?

Although cotton is the most used textile vegetable fiber in the textile world, organic cotton does not (yet) benefit from this craze. Indeed, according to a Textile Exchange report, in 2021 the production of organic cotton fibers was estimated at 1.4% of the global cotton crop. Among the largest organic cotton producing countries, we can mention India (38%), Turkey (24%), China (10%), Kyrgyzstan (9%), Tanzania (6%) , Kazakhstan (4%), Tajikistan (4%) and the United States (2%). Concerning Europe, here again, Greece is the European country cultivating the most organic cotton with 0.5% of world production .

So how is organic cotton different from traditional cotton?

First, organic cotton drastically reduces the percentage of water use . The main reason ? His culture. It does not require the use of chemicals (pesticides, insecticides or chemical fertilizers). Organic cotton is grown with natural fertilizer and insecticide , and does not deplete the soil , which retains water and moisture better . These practices make it possible both to optimize the use of water , to reduce greenhouse gas emissions , and to eliminate the impact of chemical products on the environment, biodiversity and people.

Second point, the cultivation of organic cotton, in addition to being more sustainable for the soil, is also more respectful of people by ensuring, thanks to labels in particular, such as the GOTS label, better working conditions and protection for cotton producers (fair remuneration, compliance with health and safety standards, no forced labor or child labor, etc.).

At Maison Izard, we are committed to promoting natural materials with the least possible impact on the environment and people. This is why we have chosen, for our cotton t-shirts, an organic cotton yarn from the United States (a country where cotton farmers receive fairer remuneration).

Linen: the plant fiber made in France!

Did you know that linen is mainly produced in France? With more than 70% of the world's flax production, France can even boast of being the world's largest player in this ecological vegetable fibre. Even if flax represents only 0.5% of the textile fibers produced in the world ( Source: Alliance For European Flax-Linen & Hemp ), the flax market has been booming over the last ten years with, for example, a number of agricultural land up by 133% between 2010 and 2020. On the other hand, this local production is mainly exported to Asia, particularly to China, to be spun. In recent years, we have witnessed the emergence of a complete production chain in Europe, from farming to weaving, including scutching, combing and spinning. Driven by these new players, the know-how of historic companies with strong local roots, and certifications such as European Flax™ and Masters of Linen™ , the European linen sector is developing more and more by positioning itself in particular on the “premium”.

But what is linen?

Millennial vegetable fiber, with characteristic blue flowers, flax is, before its transformation, a herbaceous plant which needs a temperate and humid climate to develop. This is partly why Normandy is the ideal region for its development! Renowned for its robustness , its quality and its multitude of uses , linen makes it possible to obtain comfortable , temperature-regulating and easy-care clothing, all while being a natural fiber with a low impact on the environment , which makes it makes a fiber with multiple virtues! In addition, it mixes very well with other fibers to obtain mixed fabrics (one necessarily thinks of mixed fabric, which is a mixture of cotton and linen).

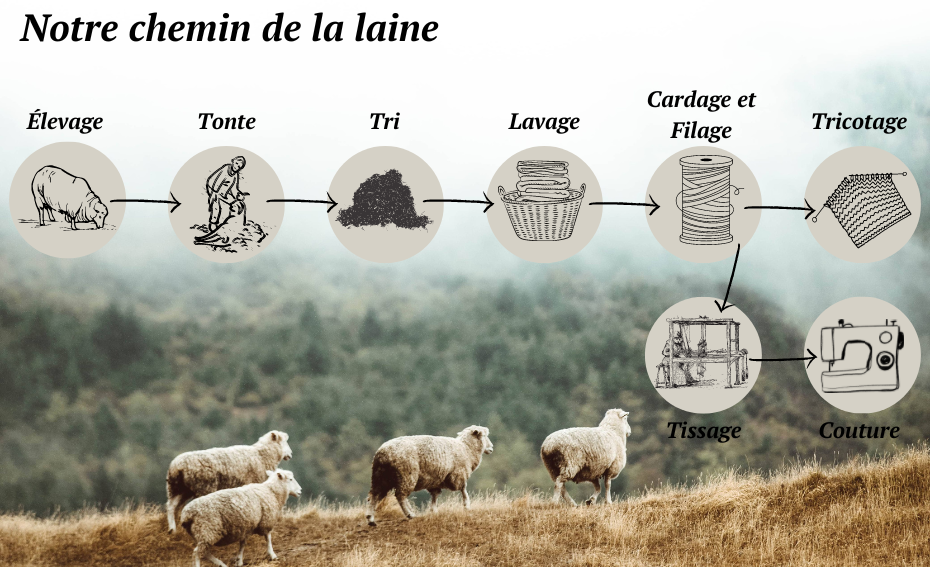

Its culture, which consumes little water and requires almost no chemicals (pesticides, insecticides, unlike the classic culture of cotton) makes it one of the most ecological cultures in the world. To go into detail, the cultivation of flax extends over 7 months, from March to September. The plants are sown in March or April and reach maturity after 100 days, with between 80 and 100 leaves per plant! It is in June that the flowering takes place, and that the blue flowers, lasting a few hours, appear and give the fields a unique beauty. Uprooting begins in July, which consists, as its name suggests, of uprooting the stems halfway up to spread them on the ground in small sheaves called windrows.

Then comes the first phase of transformation, which extends between the end of July and September, from the plant to fiber: retting. Thanks to precipitation and the sun, the micro-organisms present in the soil come to eliminate the pectose which makes it possible to weld the textile fibers, fibers which are then gathered in the form of balls.

The next step is called scutching. A mechanical process that enhances the entire plant, scutching allows the extraction of flax fibers by stripping them of the wood present in the stem.

Then, after being combed and put in the form of ribbons, the locks obtained are transformed into yarn by applying a twist. Two spinning techniques are used, leading to a different use:

- “Wet” spinning : the ribbons are immersed in water heated to 60°C in order to produce fine yarns intended for clothing or household linen.

- “Dry” spinning : the ribbons are spun without having been passed through water in order to produce thicker and more rustic yarns reserved for decorative fabrics or technical uses.

Before being woven, the thread can be bleached, dyed, softened, smoothed according to the particularity of the fabric to be produced.

Let's now look at weaving, which transforms linen threads into fabrics by interlacing warp and weft threads. This operation can be done bidirectionally (the threads undergo two horizontal and vertical alignments), unidirectional (the threads are aligned in the same direction), random (technique used for short fibers) or a mixture of the three techniques mentioned above. Each of these weavings makes it possible to obtain a different fabric, which can be used in clothing as well as in household linen or furnishings. The fabrics thus obtained are then knitted, either on circular machines, or on rectilinear machines, and for the latter, made up, then cut and sewn.

Hemp: the other plant fiber made in France

Often associated with flax, hemp is one of the oldest houseplants in the world.

Born in Asia, it is distinguished by its large stems and its leaves cut into elongated and toothed leaflets, and by its very rapid growth: the plants reach maturity on average in three months and are harvested in early September. Hemp cultivation is ecological. It requires no irrigation , fertilizers or pesticides , has a very low carbon footprint , and is 0 waste . From seed to stem, the whole plant is used. Growing it also helps store CO2 in the soil, helping it to regenerate. The process that results in softer and more elastic fibers requires the use of chemicals including sodium carbonate and acetic acid. These corrosive products are not harmful for the workers who handle them and do not pollute.

Despite all its qualities, it is a fiber little used in the textile industry. It represents about 0.2% of the total textile fibers used in the world and its production was estimated at more than 280,000 tons in 2021. Speaking of production, France is the world's largest producer with nearly 47% ( Source : Textile Exchange ) of total production, followed by China with 24% . If we count all European countries, 60% of hemp is produced in Europe.

Allowing the manufacture of durable, comfortable and good for the skin clothing, hemp is the sustainable fiber par excellence, which is partly why more and more hemp blend jeans are emerging!

But then, how does hemp become a fabric?

In textile hemp, there are several types of fiber, each subject to a specific process:

- Long fibers are valued in the same way as flax (field retting, scutching, spinning and weaving). To be spun, they will be worked, as for linen, using the "wet" technique which consists of soaking the fibers in water at 60°C to soften and soften them, before applying a twist to obtain a fine and homogeneous yarn. The yarn thus obtained will be used in the field of clothing and household linen.

- The semi-long fibers are treated on the model of wool. They make it possible to obtain a more rustic and thick yarn used in particular for denim fabrics.

- The short fibers are "cottonized", that is to say to use them like cotton by working the fibers to make them sufficiently fine and of the same length. Then the fibers will be formed into ribbons which will be twisted and joined together to give the final yarn.

- The cellulosic fibers from the pulp of the stem are created chemically, like lyocell, by dissolving the latter in non-toxic liquids, then spun using a specific process. This technique makes it possible to offer fibers that are at the same time fine, resistant, light and versatile.

From a more local point of view, the hemp sector in New Aquitaine is beginning to come back to the fore. Come back, because hemp cultivation in the Southwest was relatively developed until the beginning of the 20th century before falling into disuse.

The current issues of our territory being linked to the use of water resources (oddly turned), eco-construction, the reduction of the carbon footprint and waste, and the development of short circuits, the use of this ecological fiber would be used for the food sector, the building sector, as well as for the textile sector.

The current issues of our territory being linked to the use of water resources (oddly turned), eco-construction, the reduction of the carbon footprint and waste, and the development of short circuits, the use of this ecological fiber would be used for the food sector, the building sector, as well as for the textile sector.

Other plant textile fibers

Ramie, jute, viscose or lyocell, there are still many materials of plant origin that we have not covered! Here is some information on these relatively unknown textile fibers of plant origin.

Ramie

Ramie is a plant native to China belonging to the same family as nettle. Developing in tropical, subtropical and temperate regions, it is mainly produced in Asia, but also in Mexico, Brazil or Egypt. An ancestral plant, it is experiencing a revival of use in the textile industry even if its use remains much lower than flax or hemp. Its cultivation requires little irrigation and does not involve the use of pesticides or chemical fertilizers . In addition, it is a plant that can be used for human and animal food , which multiplies its possibilities of use. The waste resulting from spinning and weaving can even be used, by mixing it with wool or cotton, to make new fabrics.

Used since the Middle Ages for making ropes, threads and clothing, this plant with smooth and shiny fibers is very resistant, easily absorbs humidity and is easy to dye. It also has bactericidal properties and improves on contact, making it a very easy-care fiber. Clothes made from ramie are soft, cool and light, but with good thermal insulation.

Jute

Jute is a plant with golden hues that grows in rather warm and humid climates, and requires little fertilizer , insecticides and pesticides . Its culture also allows an improvement of the quality of water thanks to its capacities of absorption of carbon dioxide and improves the quality of the ground since once the harvest is carried out, the waste of the plant comes to mix with the ground to create fertilizer, beneficial to future crops. 2nd most produced vegetable fiber in the world with 3 million tons of jute per year , jute is mainly produced in South Asia such as India and Bangladesh.

Silky and robust, its fibers are transformed into rolls of canvas of several meters and of different weights, hence the burlap!

Its rolls are then used to make carpets, curtains, bags and ropes, but also clothes and accessories.

Viscose, modal and lyocell: natural plant fibers?

Let us now address the special case of artificial chemical materials made from a vegetable fiber such as lyocell , modal or viscose . They now represent 6% of the materials used in the textile sector with more than 6.5 million tons of fibers produced worldwide . New materials with the wind in their sails, they come from the mixture of wood pulp (eucalyptus, hardwood, bamboo, etc.) and chemical products. Considered as ecological textile fibres, each of them has its own characteristics and issues. Although they are biodegradable and promising , their manufacture has effects on the environment . Use of chemical products endangering people living or working near production plants, requiring a lot of energy for their transformation, and requiring wood pulp in quantity, these materials are not without danger for the environment, people and biodiversity. However, labels exist, such as Ecolabel, to certify the presence of at least 25% of wood fibers from sustainably managed forests . According to Textile Exchange, it is estimated that between 55 and 60% of artificial chemical materials come from sustainably managed forests, labeled FSC or PEFC .

Let's start with viscose, an artificial chemical fiber whose ecological dimension is the most controversial.

Viscose is an artificial chemical material widely used in the textile sector, made from wood cellulose. Every year, more than 5 million tons of viscose are produced, mostly in Asia. Originally intended to become a credible alternative to silk, it is the oldest fiber produced by man. Its manufacturing process is quite simple: it involves mixing wood pulp dissolved in a chemical solution based on soda. The material obtained is pressed to become a viscous solution, which will be extruded through a die to be finally transformed into threads. The fabric obtained is fluid, smooth and shiny. Its touch is cold, it has only a low resistance to humidity and water. Fine, soft and robust, this fabric is used to make dresses, shirts, t-shirts, flowing pants and underwear. On the other hand, it is not very suitable for technical clothing and winter clothing since the material does not retain heat and does not absorb humidity.

So why is this fiber controversial?

To begin with, although viscose comes from natural vegetable fibers of cotton, bamboo or eucalyptus, its transformation into a textile material requires extremely energy-intensive and dangerous chemical processes . Indeed, the transformation process requires the use of chemicals in the form of liquid or toxic vapors for the transformation of natural fibers into viscose, products that considerably pollute the production regions . This transformation is also harmful to the health of people living in and around production plants.

In addition, the culture is not as without effect because it requires the use of pesticides and insecticides while requiring a large quantity of water and wood cellulose , thus participating in deforestation and the destruction of natural habitats. living species for the benefit of intensive monocultures of forests intended for its exploitation.

Last point, like other fibres, its production is underdeveloped in Europe , and is mainly carried out in countries where labor law regulations are less developed than in Europe.

However, there are artificial textile fibers considered more ecological than viscose: modal and lyocell (or Tencel® ).

As for viscose, these two artificial materials come from the transformation of wood pulp into textile fiber by chemical processes. For modal, wood pulp (often beech) is mixed with sodium sulfate to create the fiber. Regarding lyocell, eucalyptus, bamboo or hardwood pulp is treated with a non-toxic natural solvent. Biodegradable, these two materials also have the particularity of being manufactured in a "closed circuit" , that is to say that almost all the chemicals used are recycled and reused. In addition, the raw materials come from trees without the use of pesticides or insecticides and require only a small amount of water for their development. Regarding the finished product, the fabric obtained is strong, soft, resistant, absorbent and has a bleached effect. Can be combined with other materials such as cotton or linen, it can be used to make clothes, underwear, pajamas or household linen. On the other hand, as with viscose, these two fibers are more intended for summer or mid-season clothing because they do not retain heat and do not absorb moisture .

However, although they seem to be eco-responsible alternatives to the use of more traditional fibers, the qualities of these fibers are to be qualified.

Since production is still a minority (500,000 tons of fibers produced per year for these two fibers) and carried out mainly in China and Indonesia, we can ask ourselves the question of the development of large-scale production on forests, biodiversity and other crops intended for human consumption. In addition, the transformation process being expensive, the selling price can be felt by the end consumer.

There are still many vegetable fibers, however, their use in the textile sector is complicated or still minority, perhaps we will witness, in the years to come, the development of new vegetable textile fibers!

The first stage of our tour of textile fibers is now over, we hope that it will have been rich in lessons for you and that it will encourage you to come and meet the growers of these fibers, without which we could not display our favorite clothes.